Ahanaf Zaman

Undergraduate Engineering Student - Passionate about Space & Rockets

Email (resume upon request): [email protected]

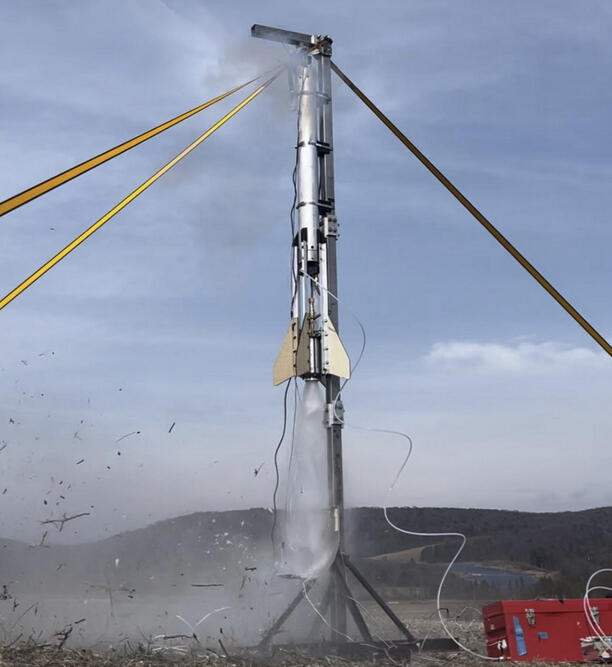

1.5 kn N2O/E85 Liquid Engine

Succesfull Hot Fire

Cold Flow Test

Hydrostatic Test

- Hot-fire: Achieved nominal ignition on first attempt; resolved valve actuation delay on-site

- Cold-flow: Verified CO2/water system a month prior; first integrated test of GSE + remote fill

- Hydrostatic: Conducted 3x tests validating tank seals, bulkhead machining, and bolt circle integrity

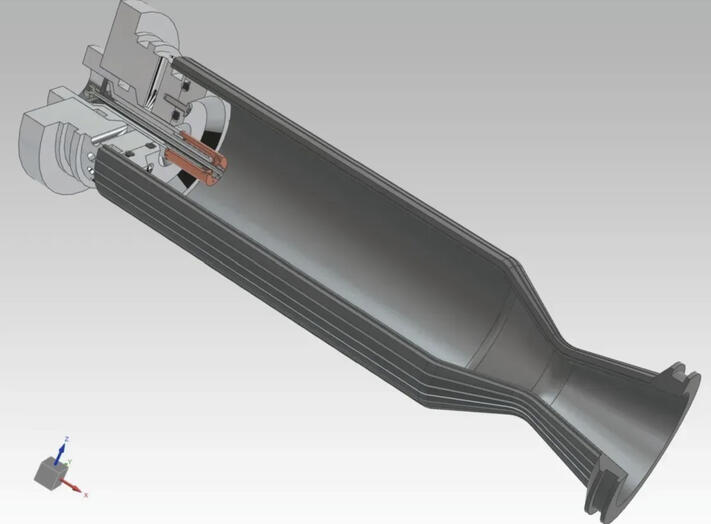

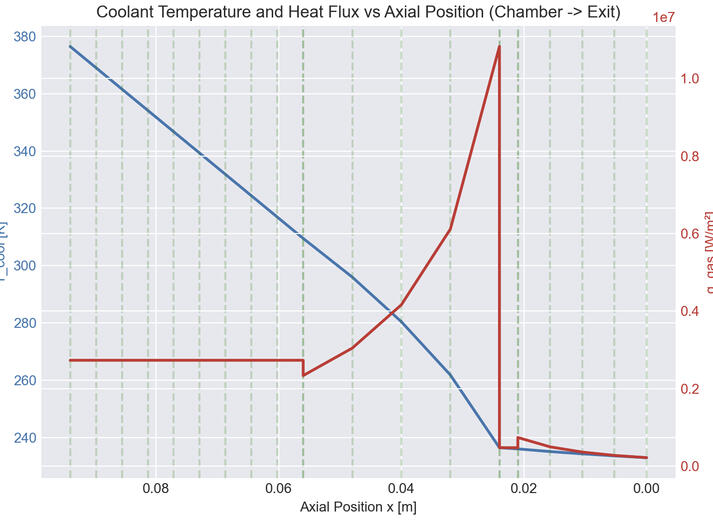

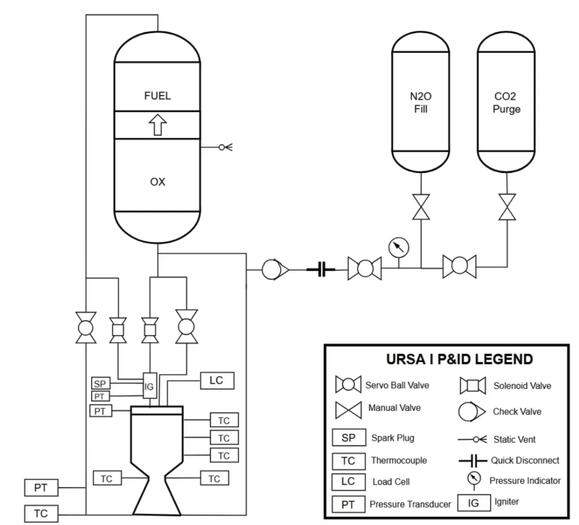

URSA - 3 kN N2O/E99 R&D

Engine CAD

Regen Solver

Ursa P&ID

- Engine CAD: Designed AISI 1018 regen-cooled chamber with pintle injector; optimized for film cooling via coolant rerouter for saddle-jacket config

- P&ID: Integrated full fill/run/purge system with multi-sensor data stream for pre/post-fire analysis

- Regen Solver: Built 1-D heat transfer model (Newton cooling, isentropic flow, Bartz Ht transfer) with Wilkes viscosity variation. Future: PDMS/silica TBCs + film-cooling features

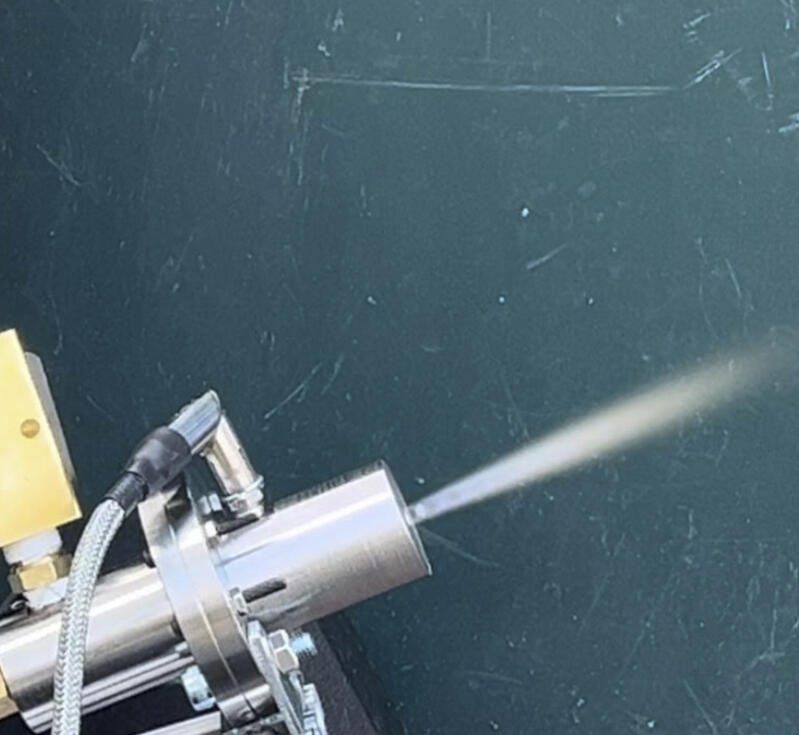

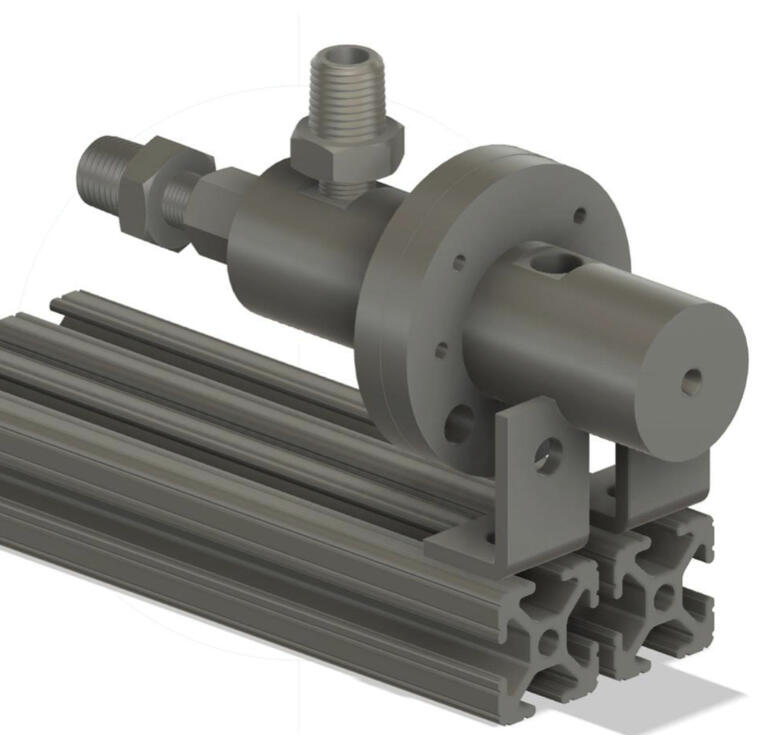

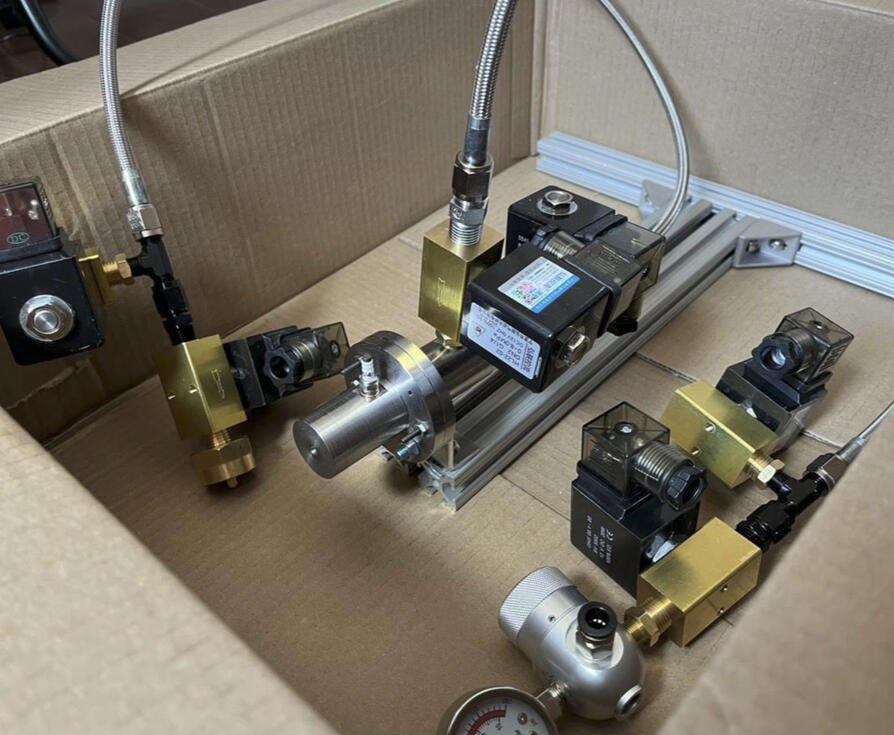

Augmented Spark Igniter (ASI)

Succesfull Hot Fire

Igniter CAD

Fluid System

- Hot-fire: Conducted 3 static fires (~70 psi, ~5 N thrust, 3s burn) with repeatable ignition

- Design: Custom nitrous-propane igniter with oxygen-clean solenoids and PTFE plumbing

Browning Rocketry

~40 kft ~Mach 3.1 Flight

Work Bench Before Flight

- Mach 3 Flight: Successfully launched to ~40 kft (~Mach 3.1, stable recovery)

- Structures: Designed and jigsaw-cut carbon/fiberglass fins and custom alignment tool to suppress roll rate in flight.